Submitted by Tom Nitza & Rich Brinkley

Plymouth

After several more work days I can report:

The rear radiator shutters are working properly. The new swivel joints

from McMaster work well. Installation was medium difficulty and several

holes had the have the threads cleaned with a tap.

There was one broken bolt for the cab shade on the fireman’s side which

resisted all efforts to drill it out. I finally decided to turn it into

a stud instead of a bold. That project will be completed by tack welding

the stud in place. Having one stud will make installation easier since

you can hang the shade on the stud and then insert the other bolts.

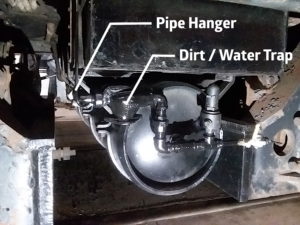

Some time was spent making a pipe hanger for the new air system piping.

This will help support the new dirt / water separator since it adds a

lot of weight. Inside the cab I enlarged the hole in the 1 inch steel

plate where the pipe enters the cab from below. I also drilled a hole in

the floor support to pass the new pipe through. At the moment the new

piping in the cab is roughed in. The next step will be to fabricate a

bracket to secure it and then tighten everything up. The final step will

be to make all the connections such as the independent brake, horn, bell

and gauge. Taps for future use by the windshield wipers and sanders will

also be installed — neither of those items were operational when we

received the locomotive.

The next scheduled work day will by Friday March 29th.

Boxcar

Work resumed on the boxcar. Six steel rods which hold the vertical and diagonal timbers in tension to increase the side walls overall strength were removed along with castings that timbers fit into and rods pass through. These castings were sand blasted and primed. They will be painted black and replaced after the upper sill beam has been replaced. The next date for work will be in two weeks, April 5th.